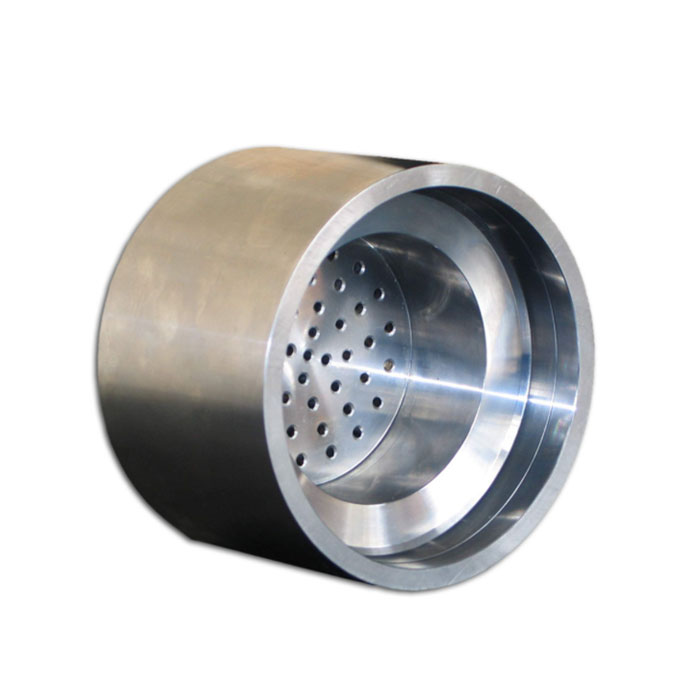

Stainless Steel Turned Parts

Brand Runxin Machinery

Product origin LiaoNing, China

Delivery time 1 month

Supply capacity Monthly capacity of 50,000 pieces

1.The beautiful surface of Stainless Steel Turned Parts and the variety of possibilities of use;

2.Stainless Steel Turned Parts have good corrosion resistance and last longer than ordinary steel parts

3.Stainless Steel Turned Parts with high finish and good weldability

The benefits of stainless steel:

As demand increases, production increases, making it more affordable than ever. Increased demand has resulted in the availability of standard and non-standard sizes. In addition, a variety of stainless steel finishes are available.

In addition to polished finishes, a range of patterned and coloured surfaces are also available. This makes it possible to find an option that suits your needs.

Stainless steel is also 100% recyclable. In fact, half of stainless steel production comes from scrap metal. This makes it a relatively environmentally friendly material.

Product features:

1. Stainless Steel Turned Parts are made of thick and good materials, high hardness, not easy to rust after long-term use

2. Stainless Steel Turned Parts have stable surface treatment, bright appearance and comfortable hand feeling

3. Various product specifications, large inventory, can be customized according to customer requirements

4. Suitable for oil pipelines, shipbuilding industry, chemical industry, construction industry and steel structure industry, etc.

Product parameters:

Product Specifications | CNC machining |

Processing material | Stainless steel |

Precision | finishing |

Processing cycle | 10 days |

surface treatment | Grinding, polishing, deburring, oxidation, sandblasting |

Our advantages and services:

Our top priorities are quality, speed and on-time delivery. We take these values very seriously because our customers are the most important part of our business. We want every customer to see us as a valued manufacturing partner for their design, prototyping and/or long-term production needs. For every client, we go through the following process to ensure the highest level of quality service:

1. Thoroughly evaluate your project and part design, and work directly with you if we recommend any design adjustments to your machined or 3D printed part to ensure its manufacturability.

2 Send professional interactive quotes directly to your email through our TAR compliant paperless parts quote platform.

3. Use optimized manufacturing methods, material selections and specified tolerances to produce your parts,

4. Check your parts after all manufacturing and finishing processes to verify tolerances and quality.

5. Deliver your parts on time according to the delivery time you choose.

6. Contact the car after you receive the zero to ensure we provide the highest level of service.

If we find any discrepancies in maintaining our quality standards and on-time delivery during this process, we will seek solutions immediately.

document preparation:

We use the best file data, build preparation, CAD and CAM software to Evaluate, and if necessary repair, edit and design your machining or 3D printing parts and assemblies to meet your desired specifications.

surface analysis:

With our industrial printer laser inspection software, we can scan and adjust for micron scan point deviation throughout the printing process and provide print quality reports for your 3D printed parts.

Overview of the company's equipment, South Korea's Hyundai Wia, Doosan Machine Tool. Horizontal machining center with very high precision.